Rocket engineering into the next round

Building upon the lessons learned from project TELL, team HEIDI aimed to increase the reliability of ARIS’ sounding rockets and strived for an award-winning system.

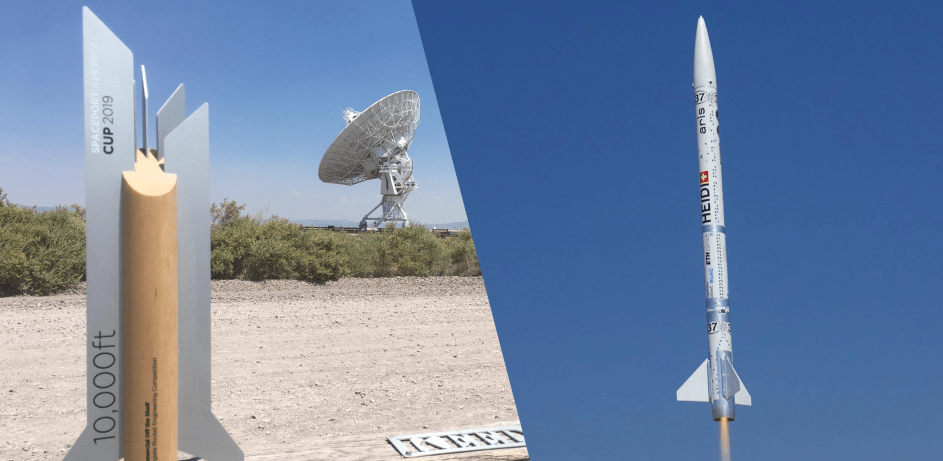

With project HEIDI, ARIS – in the second year of its existence – competed for the second time at the Spaceport America Cup in New Mexico and made the second place in its category of 10’000ft and commercial-off-the-shelf solid motors with a nominal flight. Project HEIDI was a full success.

Spaceport America Cup 2019 – Project HEIDI

In September 2018 the second sounding rocket project of ARIS – Project HEIDI launched their journey towards Spaceport America Cup 2019. Together, 30 students from ETH Zurich, HSLU and ZHAW aimed to build a launch vehicle that can reach exactly 10’000 ft while carrying a payload of 4 kg. Additionally, a highly reliable recovery system should guarantee reusability.

On the morning of the launch, the team was greeted by favourable wind conditions. With the whole team waiting anxiously, the rocket was installed on the launch pad, and the launch button was pressed. Subsequently, a stunningly beautiful flight presented itself to the spectators. After lift-off, HEIDI flew on an unperturbed, straight flight path to apogee, after which the rocket separated, and the drogue parachute deployed. Close to the ground the main parachute then deployed as expected, and the rocket could be recovered without any damage to non-replenishable parts.

MISSING TEXT

To increase reliability and maximize scoring

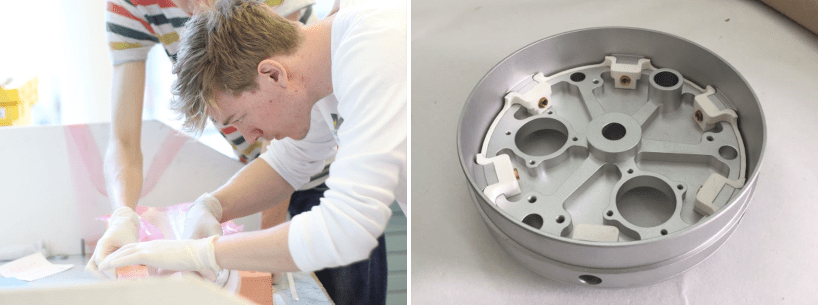

In the first phase of the project, the team combining ten different nationalities and eight fields of study, concentrated on finding the most promising concepts and designing the system. With the help of a review board consisting of experts from academia and industry, the best concepts were evaluated in a preliminary design review (PDR) in October 2018, and critical design input was gathered in a critical design review (CDR) in November 2018. Both reviews were conducted in cooperation with the EPFL Rocket Team. The focus during this phase laid on building upon the knowledge from TELL and focusing on maximum reliability.

Reliability

Critical components were analyzed, and strategies to reduce specific risks implemented in this year’s design. Testing efforts were increased up to a maiden flight before the competition.

Predictability

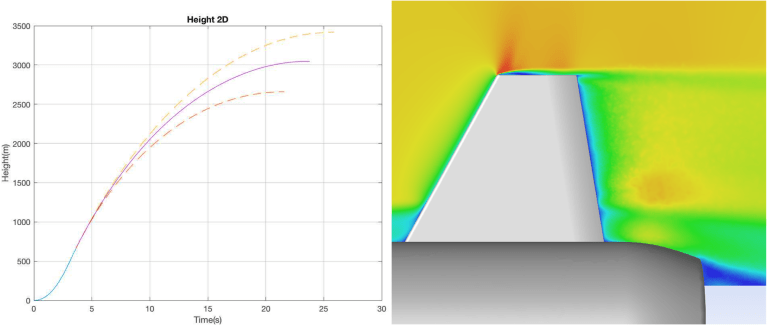

To achieve a stable and precise trajectory, the rocket’s structure was tuned for dynamic stability. The rockets shape was optimized aerodynamically to reduce drag and increase efficiency.

Improved control

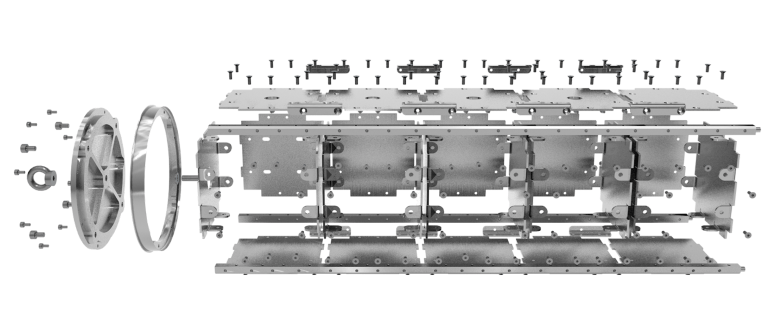

To better control the final altitude of the rocket and reach 10’000 feet as precisely as possible, the airbrake mechanism was redesigned and aerodynamically improved.

Advanced payload interface

HEIDI enables to integrate up to three experiments at the same and exchange these payloads within less than two minutes. The standardized interface structures simplify the process.

The rocket HEIDI

A sounding rocket especially developed to reach 10’000 feet above ground transporting a playload of 8.8 lbs.

Technical data

Award-winning airbrake system and algorithm

TELL won the technical achievement award named after the US rocket engineer Charles Hoult for the modelling and control of its airbrake module. The algorithm solving a chance-constrained infinite horizon optimal control problem was also presented at the 8th EUCASS conference in Madrid.

The Subsystems

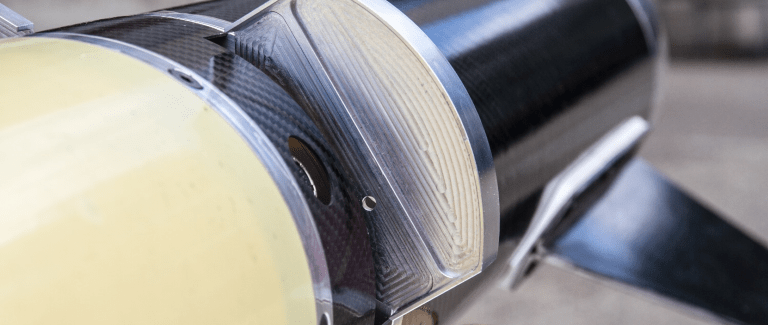

Lightweight Structure

The carbon-fiber composite rocket shell with an aluminium interface holds all systems together and ensures structural stability. The nosecone is fabricated from glass-fiber composite to let radio signals from telemetry and GPS pass. Exchangeable CFRP fins with a foam core can be dismounted for transport and replaced if damaged. Couplers and the interface bulkheads have been optimized for the loads and manufactured from aluminium.

Recovery System

Redundant avionics trigger the ejection of the nosecone by pressurizing the parachute compartment with inert CO2. As a result, two parachutes are being ejected after each other: First, a drogue after apogee to stabilize and slow down the descent to less than 32 m/s. At 400 m above ground level, the main parachute is released to reduce the descent rate to less than 9 m/s and provide a safe touch down of the rocket.

Avionics and Telemetry

To provide a live data feed throughout the flight, an X-Bee module transmits the position, system status, velocity, and position to a ground station. A WiFi transfers data within the rocket and the recovery position is acquired by a ublox GPS. The electronic hardware also stores the microcontroller and sensors for the control. All PCBs and the embedded software were student made and adapted for its use in the TELL mission.

Altitude control: airbrake system

Using the aerodynamic characteristics determined with a wind tunnel test, a student-developed algorithm controls the airbrakes that increase the drag to accurately reach the target apogee of 10’000 ft. The algorithm is solving a chance-constrained infinite horizon optimal control problem. Using Monte-Carlo simulations accounting for uncertainty and other effects, a look-up table is stored on the on-board memory and enables a simple implementation on a rocket with limited in-flight computation capabilities.

Propulsion: solid motor

A commercial solid motor composed of Ammonium Perchlorate burns for 3 s and accelerates the rocket to a maximum velocity of 300 m/s with up to 10 g. This burn provides the energy needed to bring the rocket up to 10’000 ft. TELL is built for a reloadable Aerotech M2400T commercial off-the-shelf motor. The launch is initiated by an independent ground-based ignition system using electrical matches.

It is rocket science: explosion after 1.4s

TELL had its maiden flight at the Spaceport America Cup 2018 in New Mexico. On Thursday 21. June 2018 the rocket lifted off… but after 1.4 s the flight the rocket’s commercial motor exploded.

Although shocked, the team did not give up and investigated it with experts and the manufacturer. Conclusion: a non-nominal grain burning. Most probably, team TELL just had bad luck.

Catastrophe at take-off

T – 69 minutes

After flawless preparations TELL was installed on the launch rail at 11:20h. The waiting time on the launchpad exceeded one hour.

T – 0

At 12:29h the ignition was successfully initiated, and the rocket lifted off. TELL cleared the launchpad nominally, but a tilt and/or rotation of the rocket could be observed after leaving the launch rail.

T 1.4 seconds

In the middle of the 3 seconds boost phase, the lower body of the rocket violently disintegrated, and the connection to the rocket was lost. Multiple debris could be observed. A catastrophe at take-off (CATO) was detected, and the range was closed.

The CATO was a great shock for everyone, but team TELL didn’t just take the hit and stayed on the mission. A detailed analysis on the ground with judges, experts of the competition and the manufacturer was conducted the same and following day and concluded a a malfunction of the rocket’s motor due to overpressurization from backside burning. The measured thrust curve suggested a non-nominal burning which was confirmed by the manufacturer. Most probably, just had the statistically possible bad fuel grain batch.

All parts recovered and (almost) intact

The parts of the rocket, including unburnt grain, could be recovered and were subjected to a detailed analysis. The outer structure was almost intact. The inner structure, the payload and the avionics, however, were heavily damaged. Surprisingly, no serious damage could be observed on the motor casing. The distorted lightweight fin section remains as a memorable artefact from the CATO.

Overperformance of the motor

The rocket TELL was equipped with a telemetry system and sensors in all compartments of the rocket. Post-processing of logged and transmitted data showed that the rocket experienced 16 g instead of 11 g in the short burn time until the CATO. This is 33 % more thrust than nominal.

The graph besides shows measurements from the accelerometers in the different sections of the rocket compared to the expected thrust of approximately 2400 N.

Overpressurization from backside burning

The recovered grains, the outside-burnt and burst insulation liner and the observed overperformance suggest that the fuel grain burned faster than nominal, which resulted in backside burning along the wall of the casing.

This created an abnormally high pressure in the motor and the threads of the rear closure of the motor casing weakened, leaving visible abrasion marks on the threads. As a result, the motor disintegrated, released all pressure (explosion) and stopped burning.

The intentional fail-safe mechanism by the failing threads at overpressure prevented further burning and a bigger explosion.

Never give up – the post flight evaluation after the CATO

Check out the videos of project TELL

Spaceport America Cup – Launch

Check out the video of the take-off from multiple angles and see how the rocket looked like after launch!

Spaceport America Cup – Livestream of the launch

Before the launch of the TELL rocket, the project manager tells more about the rocket and the organization.

Spaceport America Cup – House of Switzerland

We proudly represented our country with some raclette and chocolate in the desert of New Mexico.

Spaceport America Cup – Failure Analysis

Here’s a first look at the potential reasons for the break up on the ascent of our rocket during the launch.

Spaceport America Cup – Poster Session

Jonathan Firth (Exec. VP of Spaceport and Program Development of Virgin Galactics) was impressed by our airbrake design.

Spaceport America Cup – Assembly

Before our rocket is inspected by the judges, it needs to get assembled first. Check out the timelapse of the assembly!

Spaceport America Cup – the journey to the USA

We arrived safely in El Paso. We met the vice president of the Experimental Sounding Rocket Association!

Spaceport America Cup – Teaser

Time to explain what the Spaceport America Cup is and how our rocket actually works.

Windtunnel testing at Sauber Aerodynamics

Find out in this video how we prepared for finding aerodynamic parameters of our rocket with the help and know-how from Formula 1 experts of Sauber Aerodynamics in Hinwil, Switzerland.

Making of: the nosecone

The nosecone of TELL 1 is made of glass fiber prepreg. The half-shell mould is closed after the layup and subsequently cured in the autoclave at CMAS Lab of ETH Zürich. Do not feed the students while building rockets!

Full scale recovery test: launch in Val de Ruz

It is the first time the team launches a Tripoli Level Two rocket. The self-built recovery worked perfectly, and the team had a blast in the beautiful Jura region of Switzerland.

The Critical Design Review – feedback requested

With the help of our partners from industry and academia, the team figures out what the best final design of the rocket will be like. Thank you very much RUAG Space, Sauber Aerodynamics, Maxon Motor, ETH Zürich and HSLU for your education!

Use of 3D-printers for rapid testing

Christian explains to us how additive manufacturing helps to have a good idea of what the final object will actually look like.

Test-rocket for the airbrake mechanism

Passion starts early: ARIS’s first rocket launched in Kaltrbrunn, Switzerland, with ARGOS. The rocket MESTRAL I tested our first electronics of the airbrake mechanism.

The enablers of project TELL

Social Contact