The Goal

Project PROMETHEUS is developing the second generation of pressure-fed liquid rocket engines within ARIS. The goal is to provide a solid knowledge base for future liquid rocket engine projects. This includes a sound knowledge of engine design, cooling, throttling and its effect on combustion, the handling of cryogenic oxidizers and the control of such a system.

The Working Principle

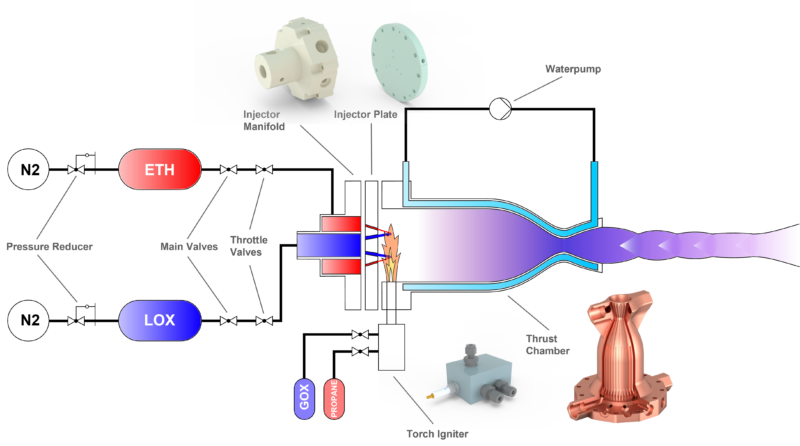

A pressure-fed liquid rocket engine is a type of rocket engine that uses high-pressure gas to force liquid fuel and oxidizer into the combustion chamber where they mix and burn to produce thrust.

The basic components of a pressure-fed liquid rocket engine include the propellant tanks, the feed system, the combustion chamber, and the nozzle:

- Propellant tanks: The rocket engine has two separate tanks, one for fuel and one for oxidizer. The tanks are pressurized to keep the fuel and oxidizer flowing into the feed system.

- Feed system: The feed system is made up of valves, pipes, and regulators that control the flow of fuel and oxidizer into the combustion chamber. The feed system is designed to allow a varying flow rate of fuel and oxidizer into the combustion chamber.

- Combustion chamber: The combustion chamber is where the fuel and oxidizer mix and burn. The combustion chamber is a cylinder with a nozzle at one end. The fuel and oxidizer are sprayed into the chamber through an injector in a precise ratio and ignited by a spark.

- Nozzle: The nozzle is designed to accelerate the hot gases produced by the burning fuel and oxidizer to produce thrust. The shape and size of the nozzle are critical to the performance of the engine.

In a pressure-fed liquid rocket engine, the propellant tanks are pressurized by a separate gas system, in our case nitrogen. The pressurized gas is used to force the liquid fuel and oxidizer into the feed system and then into the combustion chamber. The pressure in the tanks must be carefully regulated to ensure a steady flow of propellant into the combustion chamber.

The Oxidizer

…it’s getting cold. For the first time in the history of ARIS project PROMETHEUS intends to use a cryogenic oxidizer – namely liquid oxygen at a temperature of -183°C. The use of liquid oxygen will improve the performance of the engine. However, it also poses several hazards and risks that need to be carefully managed to ensure safe handling and storage.

- Fire and Explosion: Liquid oxygen is a powerful oxidizer, meaning it can rapidly accelerate combustion and can increase the intensity of any fire that it comes in contact with. Accelerated combustion is desired inside the engine, but must be prevented outside.

- Chemical Burns: Liquid oxygen is extremely cold, and it can cause severe frostbite and burns upon contact with skin or other tissues. To ensure safe handling, the team members must be equipped with the necessary safety equipment and trained accordingly.

- Compatibility Issues: Liquid oxygen can react violently with many materials, such as oil, grease, and organic compounds, creating a potential for ignition and explosion. All components of the system must therefore be checked for compatibility with liquid oxygen and replaced if necessary. In addition, the cleaning of components before they are installed in the system must be impeccable to prevent unwanted substances from entering the system.

- Expansion: Liquid oxygen evaporates with an expansion factor of roughly 860. So one liter of liquid oxygen will turn into 860 liters of gaseous oxygen. To prevent excessive pressure buildup, the system must vent itself as soon as a certain pressure value is exceeded.

The Test Engine

…where most of our tests will be performed on. NASA nailed it by calling one of their water-cooled test engines a workhorse since this is exactly what we need to conduct our firing campaign on. So far we have scheduled roughly 100 seconds of hot firing time with the goal of fully characterizing our system and investigating its throttling behavior. Our rocket engine is supposed to run on ethanol and liquid oxygen with an oxidizer-to-fuel ratio of 1,7. This results in a flame temperature of almost 3000°C. Barely any material can handle such high temperatures, thus we need a way to get rid of that heat. We approach this problem by integrating cooling channels with optimized geometry into the thrust chamber walls and using a thermally conductive material to enable high heat transfers. This is where additive manufacturing comes into play since it allows for complex interior geometries whilst keeping the desired material properties.

The Vortex Injection System

…an experimental injection system, which has the possibility to decrease the cooling needed for the engine by up to 30% and still deliver good propellant mixing characteristics. Most engines waste some performance to lessen the heat flux, which has to be absorbed. With the new injection design, these losses can be minimized or even eliminated, which would result in better overall performance. Liquid vortex injection is a novel concept in terms of research, our goal is to lay the foundation for future exploration of this technology. Since we want to compare the results of our two approaches, we designed the vortex engine with the same parameters, in terms of thrust and propellants. The injection angles we need for our designs and the reduction in complexity we gain by using additive manufacturing allows us to tackle such a design in the first place.

Social Contact