Mission

HELIOS is the 3rd generation of liquid bi-propellant rocket engine development at ARIS, building on the work of our predecessors LEA (2022) and PROMETHEUS (2023). Our goal is to conduct an engine parameter study as well as to improve the throttling capability and accuracy of our existing system, strengthening the scientific baseline and working towards a first bi-liquid flight engine. Our project is central to ARIS’ ambitious journey to breach the boundary into space, known as the Karman Line, situated at 100 kilometers above Earth’s surface.

Projects like HELIOS serve as powerful motivators, offering students a hands-on experience and the opportunity to apply theoretical knowledge. Engaging in these initiatives not only contributes to personal development but also cultivates essential skills in project management, team leadership, and engineering. The collaborative nature of teamwork is emphasized, creating a vibrant environment for sharing the spirit, fun, and enthusiasm for STEM (Science, technology, engineering and mathematics) subjects. Participants in these projects play a pivotal role in inspiring and mentoring young students, igniting their passion and encouraging them to explore the diverse and rewarding fields of engineering and math-based disciplines.

With the project of HELIOS we believe in making an impact on student-initiated projects and share our passion with our environment.

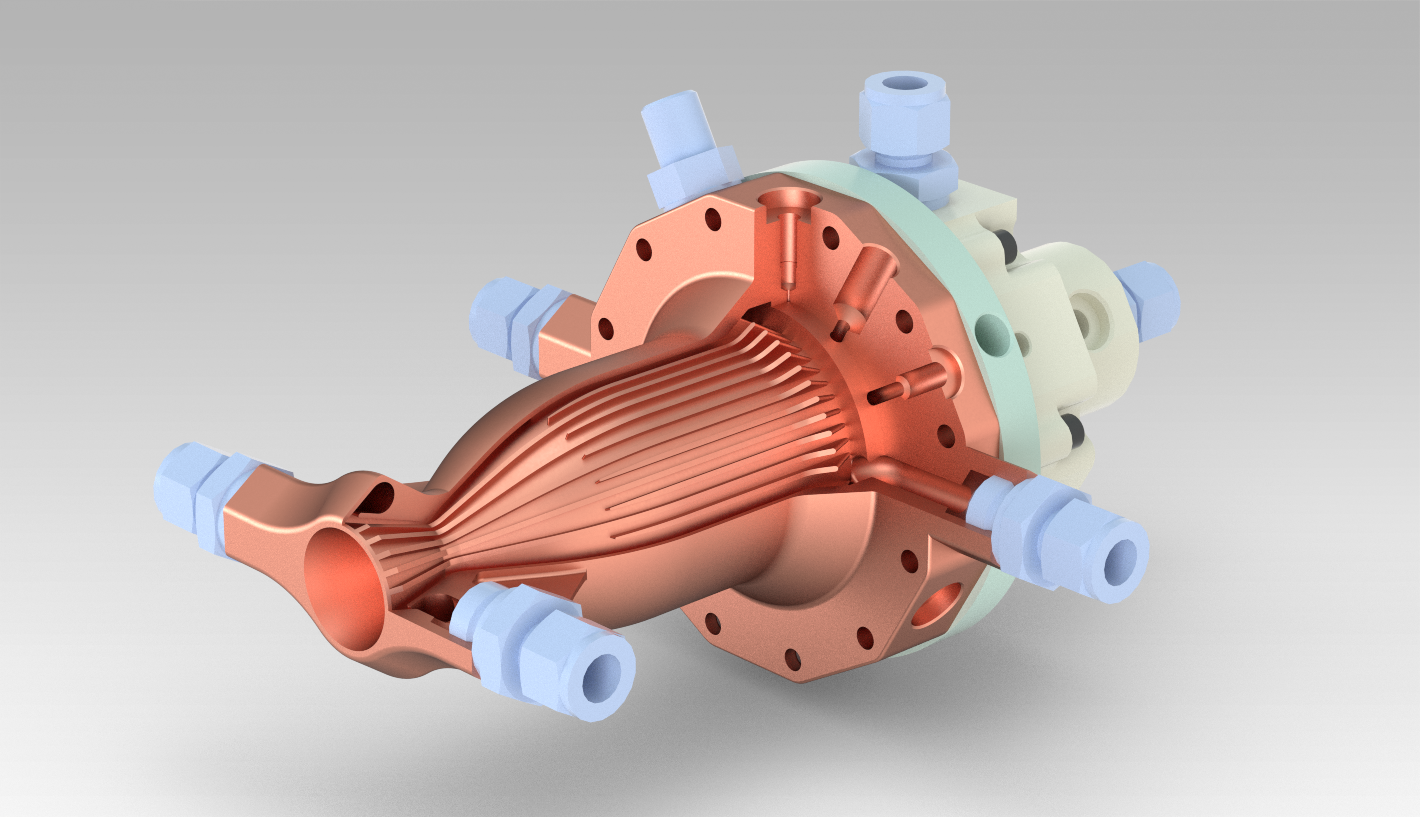

Our System

The Team

The team is composed of 30+ bachelor, master and PhD ETH students divided in four subteams: Engine, Data Acquisition and Control System (DACS) Hardware, DACS Software and Propellant Supply System (PSS). Our team has the great advantage to be a mix of experiment students who were already involved in the two first liquid rocket engine projects as well as motivated new and curious students, enabling an exciting and productive transfer of knowledge between the different generation of members.

Engineering

Engine Team

Propellant Supply System Team

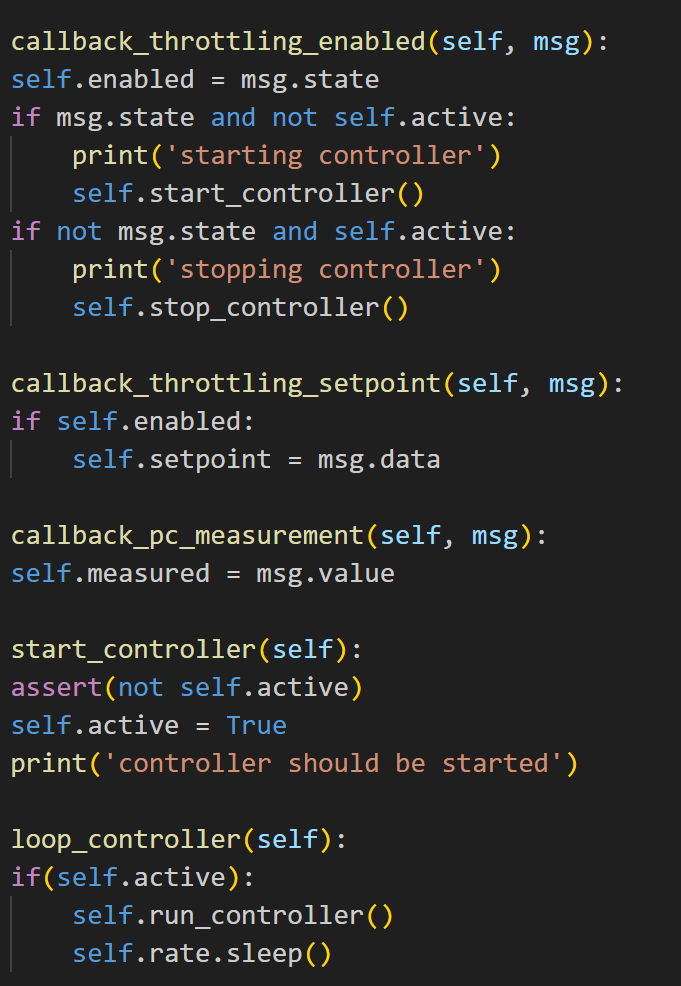

Data Acquisition and Control System Software Team

Data Acquisition and Control Systems Hardware Team

As part of Project HELIOS, DACS Hardware was able to take over the test setup from its predecessor. This setup includes 78 sensors, 23 valves, 2 throttleable

control valves, and 3 load cells. The DACS team is responsible for adding, maintaining, and replacing these electronic components as necessary to ensure the proper functioning of the system and provide the project with accurate measurements. The goal of DACS Hardware is to maintain the safety and improve the reliability of the system. Looking into the future, the team aims to further enhance the system by reducing sensor noise while increasing measurement accuracy and by improving the signal processing capability of the data acquisition system. Additionally, more possibilities for automated control and wireless communication are investigated. Lastly, additional sensors and actuators will be implemented to increase the data acquisition and control capabilities.

Social Contact